Background

Sternberg Lighting designs and builds decorative and fully functional outdoor luminaires for the municipal, landscape, higher education, and commercial markets. Founded in 1923 and based in Roselle, Illinois, Sternberg uses the latest solid-state technology and efficient and cost-effective, energy-efficient lighting solutions to meet the demands of environmental sustainability and energy conservation.

The Challenge

The challenge began when the team knew they needed to develop a better plan for order routing. The Director of Inside Sales at Sternberg dealt directly with his organization’s challenges. At the time, Sternberg was a paper-heavy company. The organization creates unique, build-to-order products – so once orders were placed, each document had to be printed out first. Then, the printed copy was moved manually around the facility to different people or departments. According to the Product Manager, “Our whole sales corner of the office was full of filing cabinets. There were well over 150 of them! We had to go into the cabinets, find and pull the printed paper document we were looking for, scan it, then put it back away.”

As you can imagine, this was an incredibly manual process that his team had to deal with daily. It also didn’t allow Sternberg to see its internal processes completely. The team didn’t have time to sort through papers and track orders manually anymore. So, they knew it was time to make the move to automated workflows.

Why Nutrient Workflow?

Sternberg researched 3-4 other workflow vendors and reviewed all their options but found Nutrient Workflow to be the best fit for their needs. Some of the main features that sealed the deal for the Director of Inside Sales and his team was how user-friendly the Nutrient Workflow application is. They felt it would be easy for department heads, who may not have an IT background, to get in and use the product. It was a bonus that someone on the team was familiar with and had used Nutrient Workflow in the past and was able to vouch for the software to be the best fit for their use cases.

The last feature that stood out to Sternberg Lighting was Nutrient Workflow’s ability to integrate with its database directly. Within the demo, Nutrient Workflow was able to show their team how easy it was to pass data between Nutrient Workflow and their internal system. This ability alone could speed up their processes by automatically filling in over 20 lines of data. Some of those, for example - fields for data, PO number, job name, etc., would all have had to be filled in manually without the ability to integrate with their database. “The fact we could leverage and pull information from the database was a huge value add for us.”

Implementation

Implementation went well. The ability to be in development mode while building workflows allowed their team to thoroughly test while building to limit any issues that may have arisen.

“It was a huge move in the right direction; it allows for reminders and transparency across multiple workflows and departments.” - The Director of Inside Sales at Sternberg Lighting.

If a hurdle ever came up, the team could overcome it by working with the Nutrient Workflow services team to troubleshoot and understand the setup to run better reports or workflows.

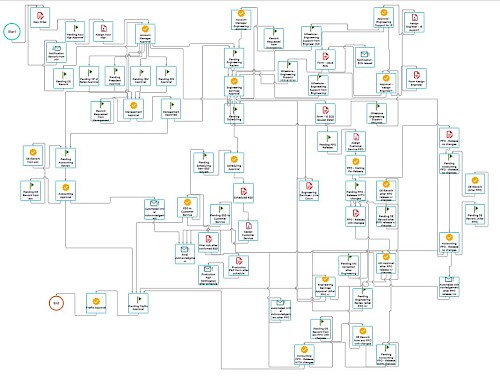

Order Processing Workflow

Order Processing Workflow

What They’ve Built Since becoming a customer in 2021, Sternberg Lighting has created workflows for internal customers in almost every department in its organization.

Some of those workflows include:

-

Order processing workflow that’ll move orders from sales through every department automatically. During this flow, the system notifies of the shipping status to the requester and when it is shipped out and expected.

-

Validation and approval workflow for new products • Workflow for requesting and delivery of customer drawings

-

Approval workflow for management to approve extensive quotes before sending them out

-

Production workflow that triggers notifications to the engineering department

-

A workflow to request and design a “Sales Order Special” that ties engineering to sales to allow maximum visibility on who is working on what task and where the design is at that moment in time.

“Orders can be completed twice as fast.” - The Director of Inside Sales at Sternberg Lighting.

Results

First and foremost, being able to stop printing orders has been a fantastic result. With the help of workflow automation, Sternberg works more efficiently by routing orders through departments automatically. “Orders can be completed twice as fast.” This process prior, from start to finish, would take roughly two weeks – after implementing Nutrient Workflow, it could be done in 1 week or less.

With automated workflows in place, it allows for complete transparency. Additionally, the reporting feature of Nutrient Workflow enables the team to review and set KPIs for employees more efficiently because of this visibility and transparency. “Because it’s down to the minute for reporting and the system documents everything – we increased the efficiency for reporting KPIs to management.”

What Will They Nutrient Workflow Next?

The team says they always find new and exciting things with Nutrient Workflow, so it’s fun to keep learning on the platform. Sternberg is constantly adding new workflows in their organization because of the incredible impact that Nutrient Workflow granted the organization. The options are endless when it comes to automating more processes in the future.