Workflow Automation for the Manufacturing Industry

Table of contents

Manufacturers are no strangers to automation. But this automation commonly used is just on the shop floor. Production automation helps reduce reliance on human labor and ensures consistency; this can also be possible in other business areas. It's time to bring automation to the administrative processes as well.

Staying ahead of the competition is a goal that all organizations work towards, especially in the manufacturing industry. Manufacturing companies face competition, logistics, hiring, and globalization challenges while managing costs. Along with these challenges, acquisitions are common in the industry, leaving room for confusion and errors. What if we told you there is an easy way to adapt more quickly to all these forces?

Let's discuss how automated software tools like workflow automation will benefit the manufacturing industry.

The Fourth Revolution for Manufacturing

In the First Industrial Revolution, steam power took over from human and animal energy sources for manufacturing. From there, it's been years of evolving to what's most efficient for the organization and workers. Next came the switch to electricity, oil, and gas. Computers came along after that, and that is when the automated shop floor became common; autonomous mobile robots (AMR) moved through factories.

So, now what? The fourth revolution, "Industry 4.0(opens in a new tab)," is the digital transformation becoming popular throughout the industry. "Digital transformation is the application of digital technologies to fundamentally impact all aspects of business and society."

This digital transformation involves replacing outdated manual processes with workflow automation. When a task is automated, it's performed the same way every time. Human workers can't manage that, no matter how hard they try.

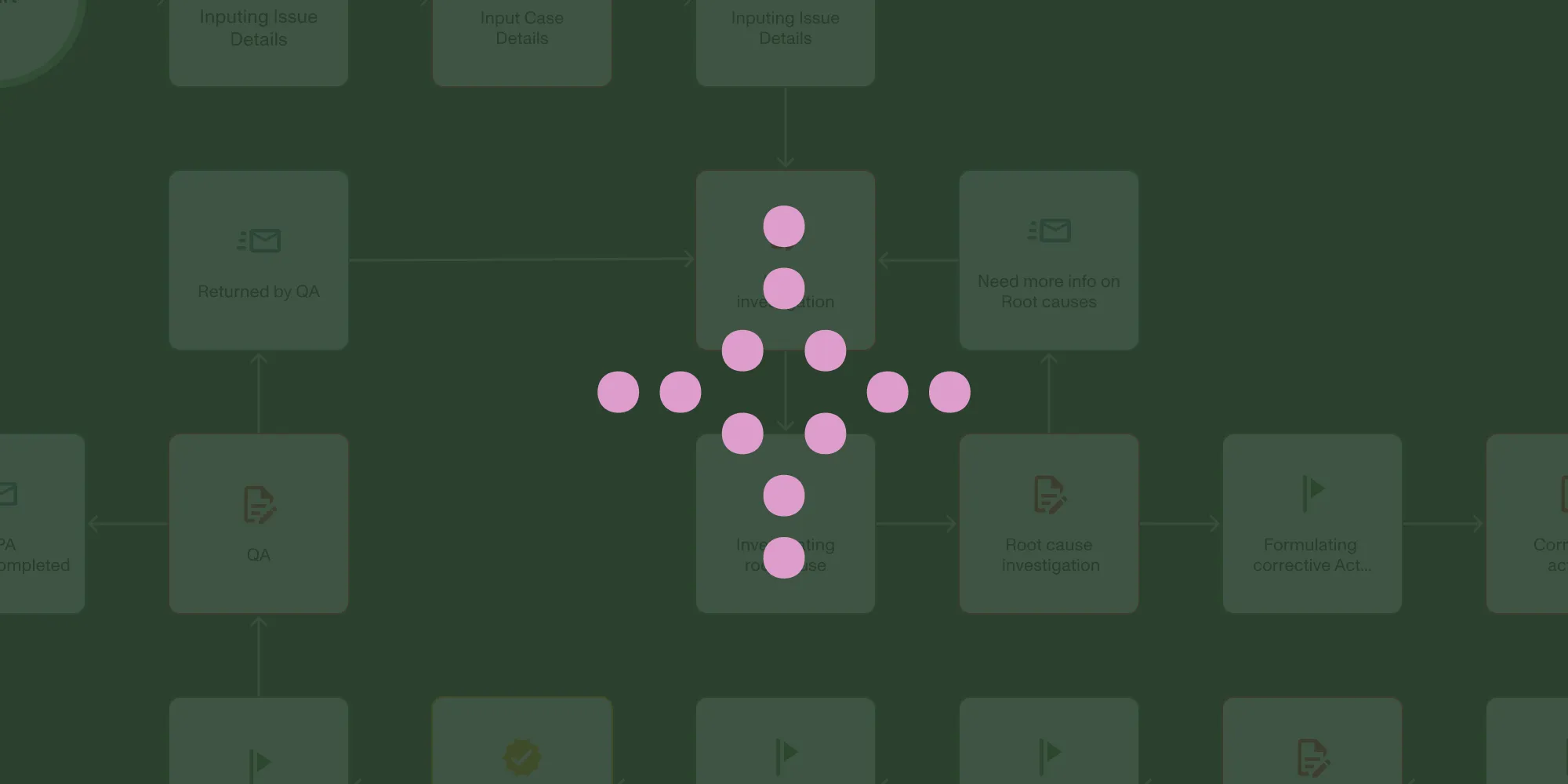

Workflow automation uses software that implements those manual processes into flow charts. It doesn't take away human involvement or decision-making but automates data movement. It is similar to a conveyor belt in a factory or an AMR, as it transfers data from one step of a process to the next.

Benefits of Workflow Automation

While there are usually human elements to any process, for instance, reviewing a document and providing approval, any workflow can be automated. Automating office workflows have similar benefits to the automation of manufacturing processes.

- Increased Efficiency: Automation streamlines processes, reduces cycle times and minimizes the need for manual intervention.

- Quicker development: By accelerating the approval processes, automation helps get products to market faster.

- Enhanced Accuracy: Automation reduces human errors and ensures consistent quality.

- Cost Savings: Automation leads to reduced labor costs.

- Scalability: Automated workflows can quickly adapt to increased demands.

Workflow Task Examples

Workflows are a series of tasks that can be automated, such as safety reporting, document approvals, product development, or any other workflow your organization needs. Some workflow task examples are:

- Pulling data from a system and preparing it for use

- Providing an answer (yes, no, data point, file attachment, etc.)

- Pushing data into a system (CRM, HRIS, ERP, etc.)

- Assigning an action to someone

- Importing data from a file like Excel

- Completing a form either manually or through RPA

Use Cases Examples

Capital and Operational Expenditure Requests

Manufacturing companies face a significant risk of errors, delays, compliance, and visibility with the volume of submitted capital expenditure requests. A compliant and consistent workflow for handling these requests can significantly reduce risk and lead to faster returns on capital spending.

Product Lifecycle Development

Manufacturing companies can optimize product development cycles by structuring workflows around R&D, quality, production, packaging, and marketing, leading to faster product launches.

Quality Control

Automated workflow management replaces inefficient and error-prone paper-based quality management systems. This leads to increased compliance and improved quality standards.

Case Study

Sternberg Lighting

Derek from Sternberg Lighting talks about how they were a paper-heavy company before automation and how Nutrient Workflow cut their sales process in half.

As you can see, there are many benefits to implementing automation in the office side of the manufacturing industry. Join the fourth revolution and stay up with the competition. Nutrient Workflow knows the manufacturing industry. We've worked with companies like BP, Sternberg Lighting, US Pipe, and Exacto. It's a unique industry, and we thrive in it. Request a personalized demo and see how our software can help your organization become more efficient.