Automated workflow management for food and beverage companies

Table of contents

In today’s highly competitive food and beverage industry, companies must optimize their operations to meet customer demands while maintaining quality and compliance. Automated workflow management is a solution that can help food and beverage companies improve efficiency, reduce errors, maintain regulatory compliance, and enhance quality control. This blog will discuss how automated workflow management can benefit food and beverage companies.

Streamlined production processes

One of the main benefits of automated workflow management is the ability to streamline production processes. Food and beverage companies have multiple production steps, and automated workflow management can automate many of these processes, reducing manual labor, minimizing errors, and improving quality. This can also lead to faster production cycles and a quicker time to market.

Increased visibility and control

Workflow automation gives food and beverage companies real-time visibility and control over their operations. Companies can quickly identify bottlenecks and make informed decisions by tracking key metrics for better visibility and control.

As an example, Nutrient Workflow helped Red Bull’s organization become more organized, accountable, and systematic.

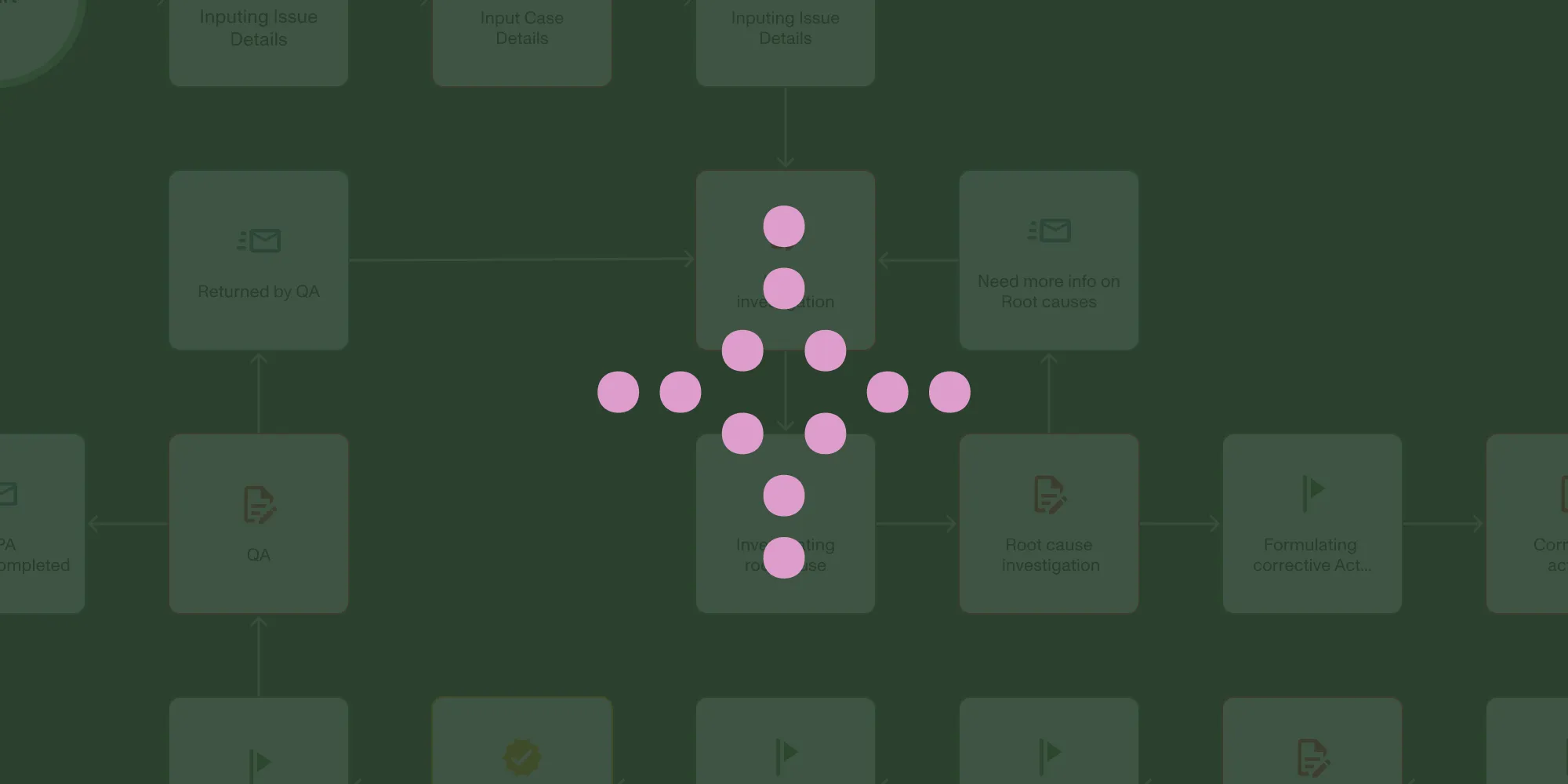

Consistent quality control

Quality control is critical in the food and beverage industry to meet regulatory requirements and customer expectations. Automated workflow management can help companies achieve consistent quality control by standardizing processes and monitoring quality in real time. Automated quality control can detect errors, non-compliance, and other issues before they become problems, saving companies time and money.

Download our finance workflow automation for manufacturing eBook!

Compliance and risk management

Food and beverage companies are subject to various regulations, including food safety, labeling, and packaging requirements. Automated workflow management can help companies comply with these regulations by providing a centralized system for tracking and reporting compliance data. This can help reduce the risk of non-compliance, recalls, and reputation damage.

Enhanced collaboration and communication

Collaboration and communication are essential to optimizing operations and improving quality. Automated workflows can enhance collaboration by providing a centralized platform like a dashboard for employees to see reports, assign tasks, and provide feedback. This can help reduce miscommunication, improve department collaboration, and streamline production processes.

Some of the ways Workflow Automation can help food and beverage organizations are by:

- Purchase requests

- Vendor and contract approvals

- Capital expenditure requests

- Timesheet approvals

- Invoice approvals

In conclusion, automated workflow management can help food and beverage companies improve operations, enhance quality control, and ensure regulatory compliance. With streamlined production processes, food and beverage companies can optimize their operations and remain competitive in a rapidly changing industry.

Watch our two-minute demo